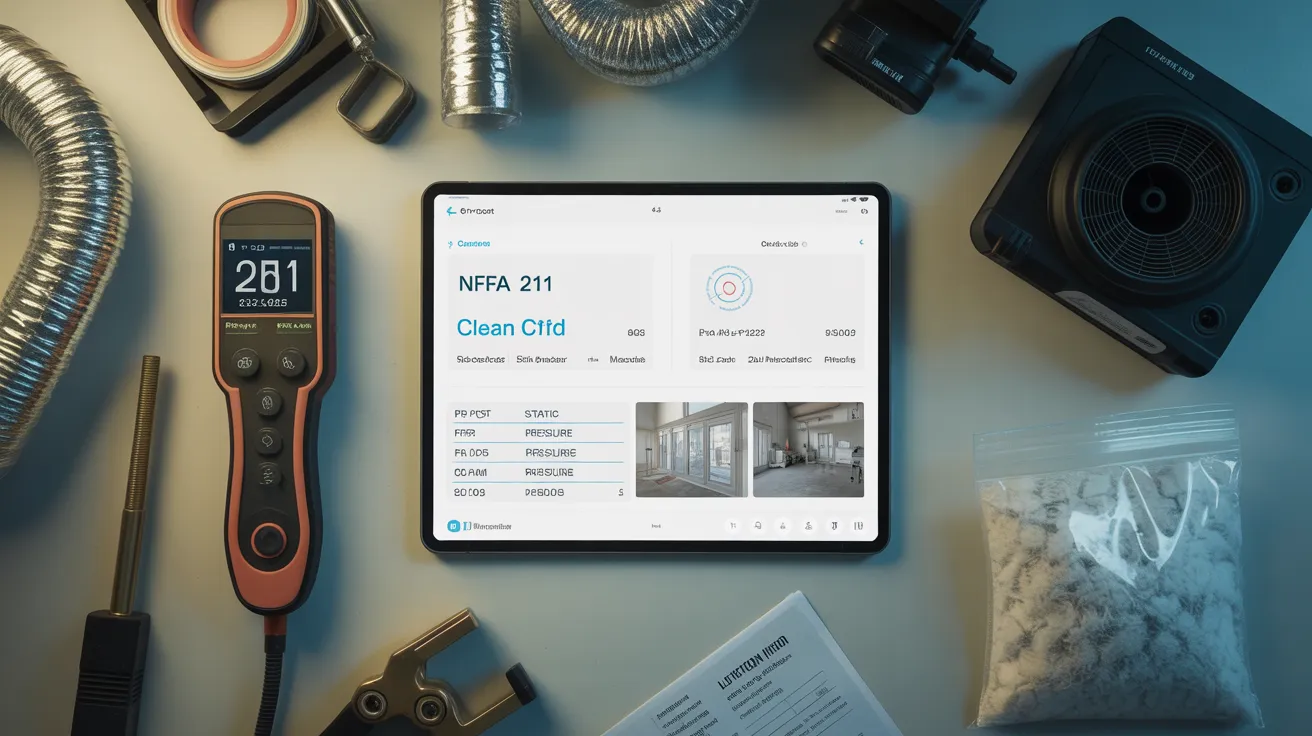

Looking for specialized West Palm Beach dryer vent cleaning professionals? We offer reliable, code‑compliant airflow using HEPA‑contained extraction, rotary brushing, and instrumented verification. You'll experience faster drying times, reduced fire risk, and improved indoor air quality in our coastal humidity. We comprehensively evaluate run length, elbows, materials, and termination according to NFPA 211/IMC, then report pre/post CFM, static pressure, temperature rise, and photos. We resolve crushed flex, seal joints with UL foil tape, and verify damper function. Discover how we deliver measurable improvements today.

Main Highlights

- Certified dryer vent experts serving West Palm Beach, enhancing safety from fires, indoor air quality, and power efficiency according to NFPA 211 and manufacturer specifications.

- Comprehensive cleaning: including HEPA negative-pressure capture, rotary brushing, termination hood cleaning, and UL-2158A certified repairs and sealing.

- Comprehensive diagnostic verification including airflow and static pressure assessments, temperature rise verification, and amperage monitoring; complete with before and after documentation and detailed test results.

- Fast response when you notice warning indicators: extended drying cycles, hot units, unpleasant aromas, reduced exterior exhaust, or activated thermal fuses.

- Oceanfront-optimized options for managing humidity, condensation, and corrosion challenges; providing complete care solutions for houses, homeowner associations, and commercial properties.

Why Dryer Vent Cleaning is Essential in West Palm Beach

Because lint collection is a primary cause of residential fires, regular dryer vent cleaning in West Palm Beach is a crucial safety task that reduces fire hazard, enhances airflow, and ensures equipment according to manufacturer and NFPA 211/CSA C22.1 specifications. You'll also safeguard wiring, terminations, and junction ducts from thermal strain and excessive pressure. By removing obstructions, you recover design static pressure, maximize exhaust velocity, and decrease cycle times, boosting energy efficiency and prolonging motor life.

When dealing with humid coastal environments, you need effective humidity management in your laundry space. Properly cleaned vents eliminate moisture effectively, minimizing moisture damage, mold development, and metal corrosion. Expert cleaning ensures appropriate duct system standards, including properly constructed metal walls, properly sealed joints, and proper termination clearances, while checking precise gas and electrical connections and vent damper performance. This guarantees safe, code-compliant operation throughout the year.

Critical Signs Your Dryer Vent Needs Urgent Attention

When your dryer shows heat stress, airflow restriction, or electrical/gas anomalies, consider these red flags that demand quick action. Should the dryer's surface or door become extremely hot, the exhaust duct could be obstructed. Longer-than-normal drying periods point to reduced airflow and pressure issues in the vent configuration. Stale, damp smells suggests moisture buildup from poor exhaust flow. The appearance of lint near the exterior vent, backdraft damper stuck in position, or compromised duct work all indicate restricted airflow.

Look out for a weak exhaust flow at the termination, a tripped thermal fuse, or repeated cycling on the high‑limit thermostat. Heat discoloration, shaking ducts, or rattling elbows point to inadequate support or fasteners. When you observe the gas burner rapidly cycling or notice erratic amperage, immediately shut down the unit and book a vent assessment.

Indoor Air Quality and Fire Safety Advantages

Even though a dryer might seem ordinary, the venting system represents a major fire risk if lint accumulates or air movement decreases. You lower fire dangers by keeping duct sizes at specification, using metal connections, and maintaining code-compliant vent endings. Sufficient air movement minimizes heat accumulation, improves smoke safety, and reduces combustible lint buildup. Furthermore, you safeguard occupants from dangerous gas infiltration when gas dryers can vent properly and connections stay sealed.

Clean ducts boost interior air quality. Efficient air filtration via the equipment and unobstructed exhaust facilitate allergen elimination by capturing dust, pet dander, and contaminants instead of recirculating them. Controlled exhaust enhances humidity control, minimizing dampness problems and wall cavity condensation. Shorter cycles mean decreased thermal stress, prolonging fabric lifespan. Adhering to NFPA 211/54 clearances and UL-listed components ensures reliability and wellbeing.

Our Trusted Dryer Vent Cleaning Method

We begin with a comprehensive inspection and code compliance check to pinpoint ventilation obstructions, duct damage, and exhaust issues. We then perform thorough removal of lint and debris using proper agitation and negative-pressure collection to eliminate scattering. In conclusion, we validate results with calibrated airflow testing and certify that exhaust function satisfies both manufacturer guidelines and local regulations.

Evaluation and Inspection

Before any work begins, our technicians conduct a detailed inspection and building code assessment to determine baseline conditions and detect potential hazards. We begin with a visual inspection of the coupling hose, vent path, termination cap, and distances to confirm UL-listed components, correct routing, and properly fastened connections. We check duct composition, length, and equivalent elbows in accordance with manufacturer specifications and Florida Building Code requirements.

We measure airflow, static pressure, and backdraft damper operation to identify blockages or incorrect termination. We carry out moisture analysis at the coupling, lint screen, and outside termination to spot moisture problems or crushed ducts. We inspect gas dryer combustion air supply, exhaust clearances, and electrical grounding. You'll receive documented results, prioritized safety concerns, and recommended fixes prior to additional work.

Debris and Lint Removal

Once we've recorded initial conditions, we advance immediately into removing accumulated lint and debris using methods specifically matched to your dryer vent's characteristics. We first isolate power, protect the appliance, and set up HEPA-grade collection to maintain negative pressure. You'll watch us utilize specialized rotating brushes or pneumatic agitation tools matched to the duct diameter, effectively removing compacted dryer lint and vent debris without compromising fittings or flexible sections.

We begin from termination to the equipment, carefully cleaning elbows, seams, and junction connectors, then performing antistatic vacuum cleaning to avoid re-contamination. We carefully bag and document the extracted debris for your records. We maintain the hood, bird screen, and damper, ensuring proper operation. Finally, we check and re-seat the clamps, confirm screw tightness, and replace any noncompliant plastic or foil connections with UL-2158A listed parts.

Airflow Testing Verification

Validate efficiency through instrumented airflow testing. Once debris is cleared, you must check system efficiency using calibrated diagnostic instruments including anemometers, manometers, and hygrometers. Establish baseline readings at the exterior vent with the dryer running and properly connected on a timed cycle. Log duct static pressure, velocity, and volumetric flow. Evaluate the readings against factory guidelines and ACCA/ASHRAE guidelines to ensure safe function.

Conduct pressure measurements at key locations such as connector hose, appliance collar, exterior hood, and inline fittings. Detect irregular pressure drops that indicate residual blockage, compressed flex, or faulty backdraft damper. Confirm that exhaust flow successfully eliminates lint while staying within code requirements for flex duct.

Record ambient humidity and temperature readings to help understand operational data. When targets are not achieved, specify suitable remedial steps. Conclude by incorporating performance results to service records for future reference and compliance requirements.

Professional Tools and Techniques We Employ

Though all homes are unique, we utilize a systematic equipment to thoroughly clean vents and comply with code. You receive a documented approach that focuses on fire safety and efficient airflow. We begin with automated scanning to document the full duct path, check elbows, and locate constrictions without dismantling finishes. Subsequently, we use thermal imaging to identify hidden heat anomalies indicating lint buildup, crushed flex, or separated joints.

We utilize rotary-brush shafts calibrated for duct diameter, then capture debris using HEPA-filtered negative pressure eliminating indoor re-entrainment. Where code permits, we use flexible cleaning heads for fragile sections and nylon rods for metal ductwork. We monitor motor amperage, inspect backdraft damper operation, and secure joints using UL-listed foil tape, instead of conventional duct tape, providing reliable, code-compliant results.

Services for Homes, Condos, and Businesses

We deliver specialized residential services that match system requirements and component specifications while meeting NFPA 211 and manufacturer requirements. For condos, we manage entry coordination, document results, and adhere to HOA bylaws and local fire code to keep shared shafts and booster fans compliant. Commercial clients benefit from commercial-grade maintenance plans with regular cleaning, airflow monitoring, and detailed reports to meet OSHA expectations and AHJ assessments.

Tailored Residential Services

Designed specifically for various living settings, our customized residential dryer vent services tackle the unique building standards, air circulation needs, and accessibility issues present in various residential properties including houses, condominiums, and townhouses. We initiate with a comprehensive evaluation aligned with NFPA 211 and IRC guidelines, measuring key elements such as ductwork, bends, exits, and construction materials. Following this, we clear lint and debris using professional rotary brushing and HEPA-contained negative pressure to restore manufacturer-specified performance levels.

We maximize energy efficiency by verifying vent run geometry, correcting crushed flex, taping joints with UL-listed foil tape, and calibrating proper backdraft damper tension. You'll receive documentation: pre/post airflow, amp draw, temperature rise, and photos. For West Palm Beach humidity, we suggest seasonal scheduling prior to peak dryer use, providing optimal safety, accelerated drying, and minimal system wear.

HOA Compliance Requirements

Due to the consolidated risks in multi-unit buildings, our condominium compliance service coordinates dryer vent maintenance with industry standards including NFPA 211, NEC, and International Building Codes, plus your governing documents and coverage mandates. We standardize scope, access protocols, and documentation to satisfy association requirements while minimizing resident impact.

We start with safety evaluations of ventilation shafts and internal duct systems, assessing material type, run length, termination, air dampers, and ventilation systems. We'll provide deficiency lists prioritized by hazard, photographic proof, and remediation strategies. Our experts clear obstructions, remove foil or vinyl flex where prohibited, apply certified sealants to connections, and set service intervals according to usage and debris accumulation.

All reports are timestamped and recorded, maintain detailed unit participation records, and deliver comprehensive service verification for insurers, boards, and fire inspectors.

Professional Maintenance Solutions

While fire risk escalates with lint buildup and runtime, our professional maintenance solutions standardize dryer vent maintenance for houses, apartments, and commercial spaces under the same code-compliant framework. You'll get NFPA 211/54-aligned assessments, air circulation analysis, and documented cleaning intervals aligned with occupancy and utilization.

We establish preventive maintenance contracts that define maintenance schedules and response commitments, protecting you from unplanned downtime and citations. Our experienced technicians inspect correct duct installations, termination, and backdraft damper function, then assess static pressure and velocity to validate operational standards. We clear impediments, repair connections, balance multi-unit risers, and replace compromised flexible ducts with metal ducting where required.

You will receive detailed time-stamped documentation, pre and post readings, and remediation documentation-crucial evidence for insurance purposes, regulatory evaluations, and committee reviews.

When to Schedule Your Dryer Vent Maintenance

It's advisable to plan professional dryer vent cleaning every 12 months, or more frequently if your dryer sees heavy use (multiple loads daily), your vent ducting is extensive, or you detect warning indicators like clothes taking longer to dry, excess lint buildup, or burning odors. In West Palm Beach's humid climate, lint will become damp, stick to duct walls, and impede ventilation faster, so don't forget to maintain annual service intervals. Plan maintenance according to use: quarterly for business settings or large households; semiannual for standard households; annual for minimal use.

Create periodic maintenance reminders at the start of dryer season and hurricane season to verify air circulation, vent flap operation, and UL-2158A transition duct condition. Remember to confirm outside vent spacing, vent guard integrity, and verify that airflow meets recommended CFM requirements and local building codes.

Complete Pricing Information and Inclusions

After setting your service interval, you'll know exactly what you're paying for. You'll get detailed quotes before any work begins, with parameters based on vent length, termination points, and code-access constraints. Our service includes mechanical agitation, HEPA-contained extraction, booster fan inspection, flow rate testing (pre/post CFM), and exit point cleaning. If needed, we note bird-guard replacement and approved connector modifications.

Choose flat rate pricing for basic single-run setups, or choose service packages combining airflow balancing, cleaning, and lint alarm setup. We record everything with photos, static pressure readings, and NFPA 211/IMC compliance notes. Our detailed invoices list materials, labor, access charges, and applicable roof-safety fees. No hidden costs check here - additional work (repairs, rerouting, or remediation) requires your written authorization prior to starting.

Customer Feedback and Local Achievement Stories

Because results speak louder than promises, our customers report quantifiable gains: improved drying efficiency, documented CFM gains, and static pressure restoration to code-compliant levels. In Client feedback, you'll discover measured results: cycles accelerated by 30-50%, fans restored to factory specifications, and lint accumulation decreased to safe levels. You benefit from NFPA 211-aligned methods, UL-certified parts, and proven flow rate increases.

Local milestones feature apartment complexes in West Palm Beach clearing HOA safety inspections after addressing crushed flex runs and faulty terminations. Home inspectors report a decrease in dryer-fire dangers where we've resolved extended duct resistance and restored backdraft damper operation. We provide before/after meter measurements, photos, and recommended intervals. This clear documentation helps you manage filter changes, monitor energy use, and verify code compliance.

Common Questions

Are All Your Technicians Licensed, Insured, and Vetted?

Indeed. We provide licensed technicians who adhere to state and local codes, hold current certifications, and follow manufacturer specifications. We carry full liability and workers' compensation insurance for your safety. We perform thorough background checks and regular safety training, encompassing lockout/tagout, confined space awareness, and NFPA 211/IMC compliance. We log procedures, check clearances, and evaluate airflow and termination integrity. We provide transparent reporting, controlled access for keys, and visually documented results.

Are Same-Day and Emergency Dryer Vent Services Available?

Of course, we accommodate immediate dryer vent maintenance. We focus on life-safety hazards, blocked vents, and temperature concerns with emergency bookings and quick turnaround. We deliver a thorough evaluation, airflow and static-pressure tests, and system cleaning to factory specifications. We inspect duct materials, proper termination, and clearances, and record results. You'll receive complete inspection results, image evidence, and maintenance advice, with guaranteed service and completion confirmation.

Are You Able to Service High or Hard-To-Access Exhaust Vents?

Indeed, we maintain difficult-to-access exhaust outlets. You work with technicians trained for rooftop access, fall protection, and confined-space procedures. We deploy anchor points, ladder stabilizers, and OSHA safety protocols. We verify termination caps, backdraft dampers, bird guards, and clearances. We employ rotary brushing, HEPA vacuums, and camera inspections to guarantee full airflow. You'll get comprehensive reports, visual documentation, and flow measurements. If needed, we replace damaged caps and repair penetrations to manufacturer specs.

Can Cleaning Void My Dryer's Manufacturer Warranty?

Regular cleaning maintenance won't void your dryer's warranty. As an example: during annual cleaning service, your service professional clears accumulated lint, optimizes airflow, verifies temperature levels, and provides code-compliant documentation. Maintaining these service records validates warranty claims through proof of proper care. Always work with certified professionals who follow NFPA 211 guidelines and manufacturer protocols, prevent unauthorized component removal, and maintain complete documentation through pictures and payment records. If existing damage is found, technicians will document it before servicing to protect your warranty coverage.

Are Before-And-After Airflow and Lint Volume Reports Available?

Yes. You receive detailed airflow measurements and a lint collection analysis following our service. We measure pre- and post-cleaning CFM measurements (CFM) using professional measuring equipment and track static pressure changes. Regarding lint, we calculate volume and weight, assess combustible buildup, and photograph findings. Reports include vent path conditions, code-compliance observations, and security suggestions. You'll see comprehensive, documented improvement data to help with maintenance planning and property management or insurance records.

Final Thoughts

You prioritize safety, efficiency, and code compliance - and so do we. The fire risk from lint accumulation is significant; the U.S. Fire Administration documents nearly 2,900 dryer fires each year, with most originating in clogged vents. Imagine a vent filled like a felt blanket restricting airflow and leading to dangerous temperature increases. Proper servicing can reduce fire risk, improve IAQ, and satisfy manufacturer and NFPA 211 standards. Be sure to schedule routine service, record findings, and confirm airflow and termination. These steps will protect your property, lower energy usage, and ensure your system operates within specifications.